It's been an unusual week here, with lots of small projects, a few things we hardly ever make, and a lot of desk work. Oh, and, hey, the driving!

It's been an unusual week here, with lots of small projects, a few things we hardly ever make, and a lot of desk work. Oh, and, hey, the driving!It's hard to believe that pillows and cushions were my bread and butter for some years, because now arthritis makes cushion making very painful. Sewing cushion covers is not too bad as long as the fabric isn't too heavy, but cutting the foam and stuffing the cushion is almost out of the question.

In a moment of weakness I agreed to make these chair pads. But they turned out so nicely that I didn't even mind. Instead of ties, these have brown snaps.

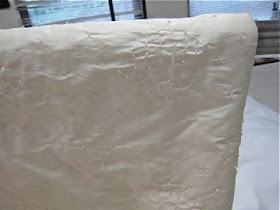

These grey velvet pillows are as soft as a kitten, and the inset pleated linen banding is a nice rustic contrast.

The trim is hand-sewn. A quick trial on the machine demonstrated that the nap of the velvet made the trim "walk" when sewing down the nap, and "drag" when sewing up the nap. It was pleasant, relaxing, rhythmic sewing.

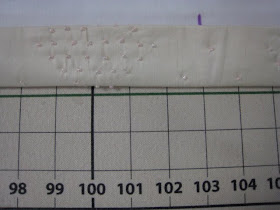

|

| 1 1/2 width panel- all pleats the same |

| |

| 1 width panel- 1st, 3rd, 5th pleats same as larger panel |

In a happy coincidence, the pleat spacing on this asymmetrical stripe worked out perfectly for a width-and-a-half pair of pinch pleated draperies. Pleating on pattern is more important to me than whether the drapery fits or not!- because, well, you can always make it fit, by making it more or less full, but if the fabric isn't pleated on pattern it just doesn't look good to me. And since these are side panels only, the exact finished width is not that important.

For the single width panels, the same pleating wasn't an option. I compromised by making the pleats and spaces a little smaller, and centering every other pleat the same as on the larger panels. That left two out of the five on the alternate stripe, so the single width panels are consistent with themselves and have at least some consistency with the other pair.