For someone mainly known as a Roman shade maker, I sure have had a LOT of drapery orders these last few months. And since I acquired a few old/new-to-me sewing machines this year, I was able to handle the volume and enjoy the process.

I still LOVE sewing draperies by hand, however! The penultimate drapery job before Christmas break was Ripplefold for 34' of window space, and these 20 widths of fabric were entirely hemmed by hand. Nicole Gray of Suite Dream designed the treatment with 4 panels, each using 7 yards of a double-wide poly-linen blend. Right now the Architrac rods are visible, but soon they'll be covered with a painted cornice. This is the installation day photo- more to come after the job is complete.

A few days before the Ripplefold, Nicole installed these 8 banded panels for a bay and two side windows.

Appropriate fabric choice is a key element of successful draperies. Here the woven-patterned banding fabric paired perfectly with the medium-weight poly-linen blend.

The hems were pressed into the face fabric before the widths were joined, eliminating the need to table the bottom separately.

I'm loving my newly acquired machines! From the straight stitch machine, the fabric moved to the new/old super-fast Rimoldi for the raw edges to be overlocked......

.....then down the line to the blindhemmer for the bottom hems.

The banding fabric was basted in place with Dofix's Bortenfix K basting adhesive before sewing to keep it from shifting. The banding was sewn at the 4" line so it could be wrapped with a full 4" on the back as well. Although I'm showing the photo here, the banding was actually the first thing done, even before the widths were joined. That meant less bulk to handle while sewing the band.

I worked in pairs so I'd be sure not to make a mistake and make more lefts than rights. The first panel took longer than it should have because I hadn't developed a method yet. After the first one I realized I'd save time by doing as much of the bottom corner as possible before laying in the lining. The edge was pressed, the bottom trimmed, and the panel laid into the Drawmatic clamp bar with the corner kept free. The hemline of the band fabric was kept loose and unpressed, so the bottom line could be manipulated a bit in case there was take-up.

I shifted the corner onto the table so I could work with it more easily. The corner weight was tag-gunned in place.

The band is folded up....

Tucked in...... (the first 4" of hem was left unstitched to allow for this step).......

And re-positioned under the clamp.

The lead edge was folded, pressed, and pinned after laying in the napped sateen lining.

The bottom corners were pinned in place. The lead edges, with the banding, were sewn by hand, and the return edges were machine blindhemmed.

My favorite thread for hand-sewing side hems is Silamide thread. It doesn't tangle, it glides easily, and has just a wee bit of give that keeps the seams from clenching up. I use a single thread for most hemming, but for drapery bottom and top corners I double the thread.

The bay window panels had two lead edges with banding, for a total of 8 panels, 13 widths, and 10 lead edges.

Quite an adventure! These 43 widths were made in addition to a set of sheer pinch pleat (14 widths), two pairs of lined and interlined top tack with decorative tape (6 widths), and two pairs of sheer lined with sheer top tack (6 widths). A total of 69 widths in the 10 days before closing for Christmas break! All side hems were machine blind-hemmed except for the ripplefold above, and the 10 banded lead edges.

Not shown: low-bulk method for tabling the tops, and the pleats being tacked with my new/old Chandler tacker- a super-time-saver!

THE BLOG IS HAVING TROUBLE WITH COMMENTS! SOMETIMES THEY DON’T GET PUBLISHED, AND WHEN THEY ARE I AM UNABLE TO REPLY TO THEM. IF THAT HAPPENS, JUST EMAIL ME AT stitchlore@gmail.com.

Looking for something specific? Check out the Topic Index, or the Search bar, just below, on the left.

Sorry about this problem!

SO.........WHAT ARE WE WORKING ON TODAY??

Friday, December 29, 2017

Friday, December 15, 2017

John's genius trusswork

It's time to show off the truss that John built for the new workroom, for hanging and leveling shades.

Derived from lighting trusswork, this frame will hold a 12' wide shade, and will raise right up to the 11' ceiling to just under the lights.

There's an easy-to-operate crank at each end, but it can be raised and lowered by just one person, as long as he/she runs back and forth a few times.

The stands are wheeled, so the frame can back up against the wall when not in use.

An assortment of clamps placed at uneven intervals give flexibility to hang different board sizes and depths. For extreme circumstances we can just drill a dustboard right into the wood frame. The back edge of this wood platform will eventually hold a drapery track for hanging panels for dressing or inspecting.

Best of all, I can work easily from either side of the shade.

It was first seriously used for an oversize shade made from a beautiful Designer's Guild herringbone semi-sheer.

This fabric was shifty and its handling required lots of TLC.

When it was time to shift the fabric on the table to finish the top, we hand-basted a line for both security and reference.

There were a couple of puckers from lax stapling, which we could see when the shade was hung.

These were easy to fix by lowering the shade and adjusting the staples from a ladder.

It's smart to marry an audio engineer!

Derived from lighting trusswork, this frame will hold a 12' wide shade, and will raise right up to the 11' ceiling to just under the lights.

An assortment of clamps placed at uneven intervals give flexibility to hang different board sizes and depths. For extreme circumstances we can just drill a dustboard right into the wood frame. The back edge of this wood platform will eventually hold a drapery track for hanging panels for dressing or inspecting.

Best of all, I can work easily from either side of the shade.

It was first seriously used for an oversize shade made from a beautiful Designer's Guild herringbone semi-sheer.

This fabric was shifty and its handling required lots of TLC.

When it was time to shift the fabric on the table to finish the top, we hand-basted a line for both security and reference.

There were a couple of puckers from lax stapling, which we could see when the shade was hung.

These were easy to fix by lowering the shade and adjusting the staples from a ladder.

It's smart to marry an audio engineer!

Wednesday, December 6, 2017

Mastering the Miter, one corner at a time

A miter queen I definitely am not- I know a miter queen or two, but I'm not one of them! I have to carefully think my way through it every time. As with many fabrication tasks, such as installing zippers in pillows, the only way to become proficient is to practice, practice, practice.

For these pillows, precision was key. The Samuel and Sons 2" woven braid had to be turned into a 1/2" mitered flange.

When I made a trial flange, I immediately discovered that the soft braid would not hold its shape.

When I trimmed and turned the corner, there was the look I was going for! The stabilizer gave me control over the shifty tape.

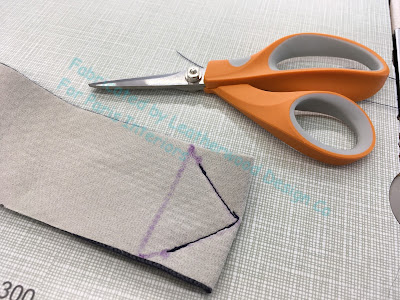

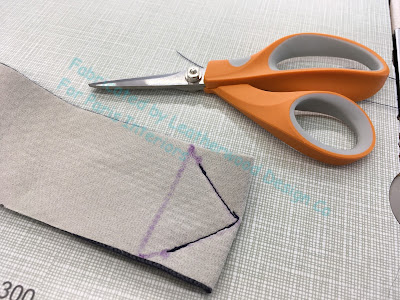

So I got out my rotary cutters and cleared my mother-of-all-cutting-mats tabletop. I needed a sharp blade for the stabilizer, so I put a fresh one in my cutter.

I cut the strips just shy of the trim width.

I learned the hard was that the tape should be ironed on OVER the stabilizer, not the other way around. A few miles of ironing later.....

Nothing for it but to plunge in and get started. Once you get the hang of it, this is actually fun.

For these pillows, precision was key. The Samuel and Sons 2" woven braid had to be turned into a 1/2" mitered flange.

When I made a trial flange, I immediately discovered that the soft braid would not hold its shape.

This was not the precise, tailored look I needed to achieve.

I made another experiment using fusible fabric stabilizer from Rowley Co. When I trimmed and turned the corner, there was the look I was going for! The stabilizer gave me control over the shifty tape.

So I got out my rotary cutters and cleared my mother-of-all-cutting-mats tabletop. I needed a sharp blade for the stabilizer, so I put a fresh one in my cutter.

I cut the strips just shy of the trim width.

I learned the hard was that the tape should be ironed on OVER the stabilizer, not the other way around. A few miles of ironing later.....

Nothing for it but to plunge in and get started. Once you get the hang of it, this is actually fun.

Maybe the Miter Queens can do the rest of this job with math, but I can't! I pinned the flange to the table to mark the exact spot for executing the next corner- another use for my can't-live-without gridded table canvas from The Workroom Channel.

The pressed fold helped make it easier to be precise.

I completed the corners one at a time, going back and forth from table to machine (it's only 3 feet away, LOL) for each step.

When they were done I laid the trim out to cut and pin the join, in the center at the bottom.

The last step before applying to the pillow face was to stay-stitch the entire perimeter just inside the final stitching line, to keep the layers from shifting.

The completed trim was sewn to the pillow face as if it were a lip cord.

I just barely tapered the corners, to help avoid pointy pillow ears.

The pillow was finished the ususal way- right sides together and a color-matched zipper. The rule for color-matching with a contrast zipper: match the trim, not the fabric. This holds true 99% of the time in my experience. Now they're ready for their new owner!

Subscribe to:

Comments (Atom)