When wool drapes beautifully, it is because the panel has the internal structure to give it the freedom to hang naturally. For this Holland and Sherry wool blackout-lined and interlined ripplefold, my biggest concern was giving the header reinforcement and support without impeding the drop of the wool face. The ripplefold tape had to be sewn by machine, but all other sewing (apart from joining the widths) was done by hand. We got to use a full complement of hand stitches in this project for Susan Marocco Interiors.

As I showed in the previous post, we carefully plotted out the ripplefold tape placement after testing it on the track.

After joining the widths, hand-hemming, and hand-sewing sewing the trim on, we prepared the header before layering in the linings, even though this mean two tablings. We fused 2" buckram to the back of the header, and sewed the ripplefold tape through the fabric and buckram by machine. Back on the table, the linings were layered in, and the interlining was held in place with a "basting stitch" at the top. These steps gave structure to the header that was invisible from the front.

The lining was folded back up and the header gently pressed in place.

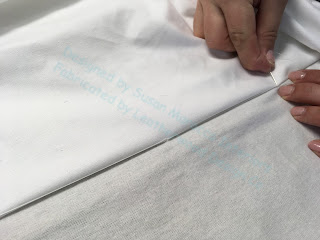

The header was secured by hand with a "back-stitch," one of my favorite hand stitches. It can't accidentally pull and cause a pucker. For this purpose, I could make half-inch stitches. (When I sew seams by hand, right sides together, I use a very tiny back-stitch. If I sew seams together while the fabric is flat on the table, I use a ladder stitch.)

At that point the panel was well-enough secured that the basting stitches could be removed. But really, they rolled slightly to the back and didn't show anyhow.

I did not want to risk having light peek through the holes in the blackout lining made by the stitches, so the last step was to fuse Dofix blackout tape over the sewing. This was probably unnecessary, but I preferred to be safe rather than sorry.

I took a similar precaution on the back side of the machine-sewn hem in the blackout lining.

Working our way across the table was a little crazy! Here is one panel partially assembled, and neatly folded to come back to the next day......

We used a lot of hand-sewing techniques for this drapery project. The trim was hand-sewn down both sides using a "ladder stitch." Unfortunately I forgot to photograph the stitching used to invisibly secure the interlining to the face at the side hem fold. We used a long, loose variation of the "serge stitch" which provides security without risk of puckering.

Internally, the layers are loosely joined at the seams with an "interlocking stitch."

The versatile "ladder stitch" was also used for the side hems.

The layers were daisy-chained at the seams at the bottom.

This is a correctly made daisy chain:

And this is not: (hahahaha!) (Guess who did this one?)

And lastly, here you can see that the bottom hems were hand-sewn with a variation of the "interlocking stitch" to keep the stitches from pulling on the fabric.

A lot of work, and time well spent to create a sublime drapery for a lovely homeowner.

THE BLOG IS HAVING TROUBLE WITH COMMENTS! SOMETIMES THEY DON’T GET PUBLISHED, AND WHEN THEY ARE I AM UNABLE TO REPLY TO THEM. IF THAT HAPPENS, JUST EMAIL ME AT stitchlore@gmail.com.

Looking for something specific? Check out the Topic Index, or the Search bar, just below, on the left.

Sorry about this problem!

SO.........WHAT ARE WE WORKING ON TODAY??

No comments:

Post a Comment