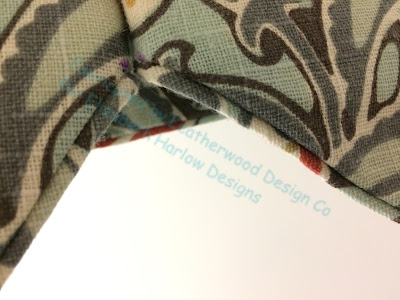

One of my favorite features on these soft cornices is self-fabric microcording. I thought it turned out beautifully on this valance. You can see the purple marks made during the planning and preparation- and upon completion, we hit those marks perfectly. They were erased after I took this picture. So today I'll go through the process of applying the microcord on the front.

We left off here on Friday: the valance pieces had been marked, cut, joined, and pressed.

My first plan was to "baste" the welting onto the face with 3/16" adhesive Jewel tape. I ran the tape around the bottom edge, splitting up the curves into a bunch of straight pieces.

I began sticking the microcord to the face along the lines I had drawn. I used 1/16" microcord which is REALLY tiny. The welting was made ahead of time, something I rarely do; I usually make it and apply it all in one step, but I did not trust that the curves would not stretch out of shape.

On the curves I carefully followed the white chalk line I made during the preparation stage. In this photo you can see the sticky tape by the glare from the lights.

However, once I began sticking the welting on, I didn't like how the tape was creating a bit of distortion, so I decided to baste the welt on by hand. In the corners I added a couple of back-stitches so the turn would stay put.

Hand-sewing really allowed me to be precise at those sharp turns. I could never have sewn it this precisely by machine.

As I sewed I peeled off the sticky tape, and as I visibly saw the fabric relax, I was glad I had made the decision to hand-baste. It was easy to see that that it was vastly better. I basted right on the machine stitching line.

And that's how I did stage one of the welting! Now the valance is turned over, straightened onto the table, and lightly pressed. From here on it will not leave this spot on the table. The various materials will be layered in and secured- and that's a story for tomorrow!