Flat-back blackout reverse mount hobbled shades. That's a mouthful, right?

It's important to remember, when talking about "blackout" lining, that

it is the LINING that is blackout, and not the TREATMENT. The lining is blackout, but the treatment is ROOM-DIMMING. The only real

blackout treatment would be plywood nailed over the window. Just about

any window treatment will have points of light bleed.

Even this three-layer blackout treatment from a few years ago- blackout drapery, shade, and cornice- allowed some light bleed.

For that reason, room-darkening is a big issue in the shade fabrication world. There are two sticking points with shades: one is the "pinholes of light" that are the consequence of stitching- the needle pierces the black inner layer of the lining and the tiny holes let light through. The other issue is the "light bleed" from the sides of shades, whether inside or outside mounted.

For this project with

Denise Wenacur, we wanted to make outside mounted room-darkening hobbled shades. Hobbled shades eliminate the pinholes of light problem because the row stitching is hidden by the "hobbles". The light bleed at the sides, however, is enhanced because the hobbles stand out from the vertical plane of the back of the shade, like this hobbled shade we made last summer:

We decided to make flat-back hobbled shades. The flat back and the reverse mount allows the shade to hug the wall as closely as possible, minimizing the light gap.

When raised, the flat back folds up with the hobbles:

I hadn't made a flat-back functioning shade in a very long time, so I was feeling my way for this project.

I fused a coordinating lining to "Silky" blackout lining (from Angels Distributing) but in retrospect, next time I'd order a color-coordinated blackout lining and use it alone. I marked the horizontal rows before taking it off the table to prepare the face.

For the face fabric, I made a mockup out of the cutoffs from the sides. I was able to work with the pattern repeat so the hobbles are pleated to pattern.

Two different finished lengths required twice the planning!

I pinned the bottom so I wouldn't forget how the layers were sandwiched.

The two layers were first joined at the bottom, at the weight bar pocket.

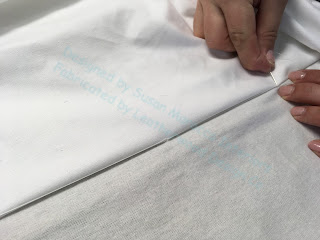

Then the shade was laid on the table and the face fabric pinned to the flat back along the rows lightly marked with a pencil.

I worked my way across, double-checking the lines on the flat back which I had marked earlier.

From the back:

And there, friends, is where the photos end! Sewing these rows is JUST A LITTLE AWKWARD, which helps explain why I have no photos of that step. After that, it was inevitable that I would forget to continue to document! But the rest of the job was pretty basic.

Rings were sewn to the back, and the shades strung (using Ring Locks) and rigged just as if it were a flat roman. These were reverse mount, which means that the fabric comes off the back of the mounting surface- in this case, Rowley's EZ-Rig headrails with velcro, positioned as far back on the mount board as possible.

Grommets in the shade allow the cords to come to the front and attach to the lift mechanism, and a blackout-lined topper blocks the grommet holes.

Pleating to pattern worked out beautifully- in this photo, see especially the bottom right which shows the pattern well:

There was another 128" wide x 27" long window for which we made a short hobbled shade that folded entirely up under the valance when raised.

This job was quite an adventure, and we were thrilled at how well it turned out!