Designer Chrissy Glenn envisioned the Fortuny pattern with banding of the same fabric in a contrasting colorway, on the lead edges, and bottom. Of course that meant accomplishing a perfect pattern match- in both directions.

Gold rope cording from Samuel and Sons defined the edges.

The project began with a day of assessment, layout, marking, rolling, re-rolling, more marking, and re-assessment. The bittersweet colorway was discontinued, so what we had in-house was all there was on the planet- and we had just- and I mean JUST- enough.

It was truly exciting to see the plan develop.

Finalization of the plan called for celebration!

Cutting required a full day of calm, quiet, complete isolation, and a generous dose of chutzpah. It was scary. Quilters will recognize the term "fussy cutting" and this was fussy cutting to the extreme.

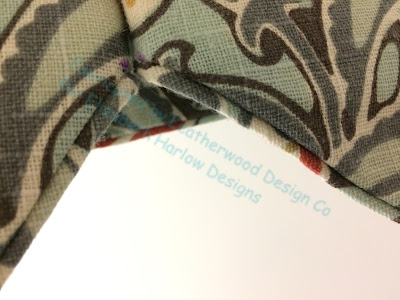

I knew that I could not manage perfect pattern matching with any ad-lib effort, so I used a double-sided adhesive tape to align the pattern. I like to use Rowley's tape for this purpose, because it can be removed easily. After pressing the edge to create a sharp, visible sewing line, I applied the tape in order to secure the layers perfectly.

The sharp crease provided a clear(-ish) stitching line.

The tape was removed right after the sewing was done, before trimming away the excess.

It is a testament to the high quality of Fortuny prints that the pattern aligned so easily. In both directions there were few adjustments to be made. This fabric isn't expensive for no reason!

The turquoise was intended to have a high translucence, so the panels were interlined with a light but dense cotton flannel, and lined with a tightly woven lightweight doublewide (seamless) cotton.

But first, we wanted to add a light-filtering layer to the bittersweet band, pressing the seams toward that side, to eliminate any shadow of the seam allowance.

Grey cotton sateen was used to reduce but not eliminate light bleed.

This grey was interlocked by hand with a herringbone stitch on all sides of both lead edge and bottom bands.

Once all twelve panels had been prepared, we began the process of assembling the layers. Here is where I have no photos- I guess at the time I thought pictures of plain white linings were too boring! We interlocked the interlining to the seams as usual, but also to the lead edges, since no lining layers were going to be rolled into the hem. They were interlocked right over the grey lining, if you can imagine that from this photo.

After assembly, the last step was to pleat and tack. Chrissy chose a two-finger top tack, tacked around the fronts of the pleats with coordinating thread.

I'll be going back to the house in the near future, and hope to take great photos then. On installation day we didn't have time to steam, dress, and stage the photos since the family was leaving for the weekend. However, even though they couldn't sleep in the room that night, they were pretty thrilled at having these to come home to!

Lots of love and gratitude to my support posse, Camille, Jen, and Rosemarie. Their work, encouragement, and advice made this project happen! And a huge shout-out to Penny from whom I learned techniques I'd never dreamed of that are now part of my daily work life.