We were able to raise the valance over the tub without drilling into the tile by mounting on wood extenders for the L-brackets.

A toned-down, straight kick-pleat valance out of Schumacher's "Woodberry" was an understated treatment for the Guest Bath window. Rather than divide the width into three equal sections, we instead left the motifs whole by slightly rearranging them and making a barely wider center section.

Sewing patterns are available for shaped box pleated valances- this is the "Sheffield Valance" from M'Fay- but after planning, cutting, and joining the individual sections, I usually just draft the shape directly onto the fabric, free-hand, with erasable pen. This allows me to customize the long and short points of the treatment. (In the years before drafting onto the fabric, I probably fabricated 5000' of Sheffield valances, so I had a feel for how to draw those curves!)

After the first return, horn, and scallop are cut, I flip the fabric to repeat the silhouette across the pieced fabric. To do this, it's essential to cut the sections accurately and straight at the top, because the top line is the reference point.

I layer the interlining and interlining, and cut around the valance.

Very importantly, I notch all three layers before moving the layers, so there are reference points in case the layers start to drift during sewing.

Now I rearrange the layers so the right sides of the face and lining are together, and the interlining on top of the face. The notches help me re-align the curves. When turned right side out, the order of the layers will be face, interlining, lip cord or welt, then lining. This sequence helps eliminate any bulge from the lip cord trim on the right side- the "important" side.

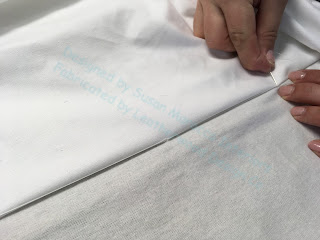

The layers are all pinned together; the lining is held back so the lip cord can be basted. (Yes, I'm using a zipper foot. Many people use a cording foot, with the welt to the bottom during sewing. Sometimes I do, too.)

The lining is folded back into place and all layers are sewn together. The seams are graded, the corners and curves are clipped, and the valance turned right side out, pressed, and mounted.

The interlining smooths out the front of the valance so no seam allowance is detectable. I learned, years ago, from reading M'Fay patterns, to determine the "important side" of the treatment, and layer accordingly.