Hey people, we are back from vacation, and are deep into the workroom move- as of today about 2/3 of the way done- by the end of today it'll be about 7/8 done.

Yesterday was exciting- the heart of the workroom, the work table, was completed! Today the sewing machines will make the trip and we'll be ready enough to actually work.

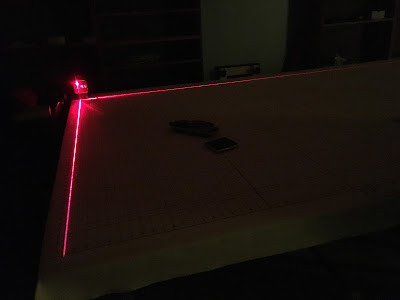

John spent the afternoon preparing, and at 7:15pm I arrived. Stretching the gridded canvas cover is a two-person job. It was dark when we finished, which made for a good photo op with the laser.

If you own a workroom and don't have a gridded canvas work table, I encourage you to consider getting one. Everything about my fabrication changed for the better once I got the first one. This brand-new spotlessly clean grid came from The Workroom Channel.

We followed the procedure in the instructions and it went smoothly, using a tape measure, an arsenal of straightedges, and our Dewalt laser. The table is layered with a plywood base, homosote, table padding from Rowley Co, and topped with the grid.

Someday I'm going to do a blog post about all of the ways I use my grid; it's vastly more useful than I ever imagined it would be, and I could not work efficiently without it. I can't even think without it.

I'll be catching up as quickly as I can with pre-vacation project stories and new workroom stories. Stay tuned!

THE BLOG IS HAVING TROUBLE WITH COMMENTS! SOMETIMES THEY DON’T GET PUBLISHED, AND WHEN THEY ARE I AM UNABLE TO REPLY TO THEM. IF THAT HAPPENS, JUST EMAIL ME AT stitchlore@gmail.com.

Looking for something specific? Check out the Topic Index, or the Search bar, just below, on the left.

Sorry about this problem!

SO.........WHAT ARE WE WORKING ON TODAY??

Showing posts with label canvas grid. Show all posts

Showing posts with label canvas grid. Show all posts

Wednesday, July 26, 2017

Friday, February 3, 2017

Hybrid Soft Cornice, part 3

Whew, this blog post is taking forever!

But this treatment was so much fun to make, I want to finish documenting it, for anyone who has the fortitude to keep reading about it. This is going to be a long post.

Here it is, one more time:

And here's where I left off at the end of the last two posts. The sections have been planned, marked, joined, cut, and pressed, laid out and aligned with the table grid.

Against the face fabric, interlining is laid in place, pressed, and cut to shape.

The buckram pieces are laid in place in the sections but not the pleats. The bottom "seam" allowance is folded up and lightly glued against the buckram and interlining. Blackout lining is then laid across it all and cut to shape like the interlining. I also ran a little glue line around the perimeter of the blackout, to keep it in place. But keep reading- it's not the glue that holds this together- it's all hand-sewn later.

For the final layer, backing is cut to shape from regular lining, and a 2" continuous bias strip sewn on to create a facing.

It's like magic when the facing is turned and pressed! This makes me happy.

The faced lining is layered over the valance, and the bottom is sewn to the welting by hand. With all the hand-basting I had already done, I figured in for a penny, in for a pound, right? No glue is holding this treatment together! I love how the hand-sewing makes a perfect welted bottom line.

At the corners the excess is folded to shape and ladder-stitched.

Since this treatment is not waterfalling off the top of the board, but instead stapled to the face of the board with a standing open box pleat header, I needed to be certain the layers would not droop inside the top. First I joined the interlining and blackout with a running stitch, enclosing the buckram so it can't budge.

Then I lock-stitched the face fabric to the interlining. Now I know that all the layers will stay put.

I folded the face fabric to the back, fold the lining under just below the top, and ladderstitched the lining across the valance.

Then I had the pleasure of turning the treatment over, folding and pressing in the pleats, and making sure the face measurement was correct! I also drew a purple-pen line 4" down from the top using a quilter's rule, and secured the pleat areas with a tag gun so I could easily ant-trail staple the valance to the covered board.

Yay! Nearly done.

I knotted the rope and hot-glued it to the staple line, and tied the cut ends tightly with matching thread.

Opening up the rope strands, I saturated the trim fiber with Rowley's fringe adhesive and let it dry.

The rope was snipped through the clear-drying glue, leaving a neat, smooth end.

Everybody was happy! Even the back is beautiful.

But this treatment was so much fun to make, I want to finish documenting it, for anyone who has the fortitude to keep reading about it. This is going to be a long post.

Here it is, one more time:

And here's where I left off at the end of the last two posts. The sections have been planned, marked, joined, cut, and pressed, laid out and aligned with the table grid.

Against the face fabric, interlining is laid in place, pressed, and cut to shape.

The buckram pieces are laid in place in the sections but not the pleats. The bottom "seam" allowance is folded up and lightly glued against the buckram and interlining. Blackout lining is then laid across it all and cut to shape like the interlining. I also ran a little glue line around the perimeter of the blackout, to keep it in place. But keep reading- it's not the glue that holds this together- it's all hand-sewn later.

For the final layer, backing is cut to shape from regular lining, and a 2" continuous bias strip sewn on to create a facing.

It's like magic when the facing is turned and pressed! This makes me happy.

The faced lining is layered over the valance, and the bottom is sewn to the welting by hand. With all the hand-basting I had already done, I figured in for a penny, in for a pound, right? No glue is holding this treatment together! I love how the hand-sewing makes a perfect welted bottom line.

At the corners the excess is folded to shape and ladder-stitched.

Since this treatment is not waterfalling off the top of the board, but instead stapled to the face of the board with a standing open box pleat header, I needed to be certain the layers would not droop inside the top. First I joined the interlining and blackout with a running stitch, enclosing the buckram so it can't budge.

Then I lock-stitched the face fabric to the interlining. Now I know that all the layers will stay put.

I folded the face fabric to the back, fold the lining under just below the top, and ladderstitched the lining across the valance.

Then I had the pleasure of turning the treatment over, folding and pressing in the pleats, and making sure the face measurement was correct! I also drew a purple-pen line 4" down from the top using a quilter's rule, and secured the pleat areas with a tag gun so I could easily ant-trail staple the valance to the covered board.

Yay! Nearly done.

I knotted the rope and hot-glued it to the staple line, and tied the cut ends tightly with matching thread.

Opening up the rope strands, I saturated the trim fiber with Rowley's fringe adhesive and let it dry.

The rope was snipped through the clear-drying glue, leaving a neat, smooth end.

Everybody was happy! Even the back is beautiful.

Friday, June 25, 2010

Tools my grandmother didn't have!

Does this fabric look familiar? Back in the winter I posted pictures of a small shade out of this fabric. It was fun using twill tape to band the edges and the shade turned out great.

The decorator wanted to use it again for this shade which is wider than the width of the fabric. We needed to find a way to join the widths.

The face fabric is a very sheer silk, with a 1/4" hemp rope woven in horizontally. The rope is very bulky, making it impossible to sew the widths, so we thought of using the twill tape to hold the widths together and at the same time hiding the join line. The twill tape is topstitched down each side, through all the layers.

This is where some modern workroom tools really made it possible to fabricate this shade with confidence.

The shade was made almost entirely on the table. Since you can see through the sheer silk and the sheer linen lining, I used the gridded canvas table to press and lay out the fabric and keep the rope lines and the lining grain line straight.

Adhesive tape was used as a basting tool. Once the half widths were positioned next to the full center width, I ran adhesive tape down the join line and pressed the twill tape into place. I also used the tape to position the twill tape used for the banding. The tapes were also pinned to keep the layers together.

Fabric staples across the top kept the fabrics from shifting while the shade went off to the machine for topstitching.

Back to the table, wrong side up, the grid again assisted in marking for the rings. As a matter of fact, I didn't even mark- I just followed the rope lines and the vertical grid lines and sewed the rings on by hand right on the table. The clear plastic rings and tan lift cord are nearly unnoticeable from the front.

The twill tape in folded in half and made a pocket for the weight bar which I sewed right behind the bottom band, following the topstitching line.

I've had my gridded canvas table for 4 or 5 years now and can't imagine going back to fabricating anything without it.

I've had my gridded canvas table for 4 or 5 years now and can't imagine going back to fabricating anything without it. Tuesday, April 13, 2010

More on Efficiency

I have been working on some hobbled shades. Since these have a lot of steps, I thought I'd showcase one shot that illustrated as many steps as possible.

I have been working on some hobbled shades. Since these have a lot of steps, I thought I'd showcase one shot that illustrated as many steps as possible.For shades, as for drapery panels, I have found that you get not only the best product but also the most efficient use of time if you leave the product on the table for as many steps as possible.

For hobbled shades, the fabric is laid face down and the lining over it, squared up, then the side hems are pressed in, but not secured yet.

The bottom will be made in various ways, depending on the style, trim if any, and the customer's preference. For these shades I folded up a double 4" hem and hand-sewed it.

Next the fold lines for the rib pockets are marked.

Here, we use disappearing purple pens. I don't know what we'd do without those!

And then the fold lines are pinned, pins all in the same direction.

As long as the straightedge is right there, the marks are made for the rings. If three lines are marked, the straightedge can be laid down to mark the remaining rows.

Now the side hems are secured. Depending on the fabric, they might be hand-sewn, adhered with adhesive tape, or blindhemmed. Machine blindhemming is a rarely used method here. We've blindhemmed side shade hems maybe twice, ever.

For these shades, adhesive tape is applied. Look at the right side of the picture where a straightedge is holding back the opened-up side hem to reveal the tape. I want to apply segments of tape leaving 1" on each side of the fold line without tape, because this tape is not nice to machine needles and I want to avoid having to sew over it.

The adhesive is a secure method but it is used only when some amount of machine stitching will be securing the layers somewhere- in this case, the rib pockets.

The twill tapes that will be "hobbling" the folds are laid out on the far right and marked, in this case in 6" increments, and brought to the sewing machine with the shades.

There are three steps the sewing machine will be used for.

At the sewing machine first the folded pocket lines will be sewn 3/4" from the fold, making a right turn at the end of the row to close the pocket on one end. I use thread that matches the face fabric, not the lining, because I want the thread to blend in at the side hems, unless it's a really dark fabric. And then, I use white for the lining sections and color matched thread for the side hem bits. A pain in the neck, but. For these shades I used a pale yellow which blended in with both lining and face fabric.

The tapes, all ready and marked, are sewn behind the bottom row on the row's stitching line.

Now the rings can be sewn and ribs inserted into the pockets, and then it goes back to the straight stitch machine which hopefully is still threaded with the matching thread to sew up the open ends of the pockets.

Ready for stapling & stringing! The shade was on the table once, and not moved til all was marked and secured.

The indispensible tools for maximum efficiency on this project: purple disappearing pen, and the gridded canvas table cover.

Tuesday, February 16, 2010

Another Sheer Shade challenge

Here is a sheer shade challenge for which I needed to find a fabrication method.

The face fabric is a silk sheer with jute rope woven in horizontally.

The face fabric is a silk sheer with jute rope woven in horizontally.

The lining is a loosely woven yet stiff linen sheer.

In the first photo you can see both fabrics laying next to the tabled shade which is being prepared.

Around the sides and bottom is a twill tape 1 3/16" wide to be folded in half and wrapped around to the back.

First I used fusible adhesive webbing to fuse the edges of the 3 sides- it is narrower than the twill tape and won't show. I wanted to do this to keep the edges from fraying.

Then I laid the tape on the back and fused it, then wrapped to the front and fused again, mitering the corners as I went.

From the front I topstitched close to the edge.

The rings are sewn on by hand, into the jute rope so no stitches show from the front.

The rings are sewn on by hand, into the jute rope so no stitches show from the front.

I wrapped the weight bar with the twill tape- it just exactly made it around the weight rod and I whip-stitched it shut, then sewed it to the shade at the rings, so the rings are mostly bearing the weight.

The last picture shows the shade from the wrong side, the rod sewn to the rings. It might need more securing but I'll wait til it's hanging to determine whether or not that will be necessary.

That's as far as I've gotten- it's now ready to be stapled and strung- and I'll add those pictures later.

I love sheer shade challenges! They're my favorite shades to make, and nearly every one presents a unique challenge. Finding the solution is my favorite part of my work.

Ta-da!

The face fabric is a silk sheer with jute rope woven in horizontally.

The face fabric is a silk sheer with jute rope woven in horizontally.The lining is a loosely woven yet stiff linen sheer.

In the first photo you can see both fabrics laying next to the tabled shade which is being prepared.

Around the sides and bottom is a twill tape 1 3/16" wide to be folded in half and wrapped around to the back.

First I used fusible adhesive webbing to fuse the edges of the 3 sides- it is narrower than the twill tape and won't show. I wanted to do this to keep the edges from fraying.

Then I laid the tape on the back and fused it, then wrapped to the front and fused again, mitering the corners as I went.

From the front I topstitched close to the edge.

The rings are sewn on by hand, into the jute rope so no stitches show from the front.

The rings are sewn on by hand, into the jute rope so no stitches show from the front.I wrapped the weight bar with the twill tape- it just exactly made it around the weight rod and I whip-stitched it shut, then sewed it to the shade at the rings, so the rings are mostly bearing the weight.

The last picture shows the shade from the wrong side, the rod sewn to the rings. It might need more securing but I'll wait til it's hanging to determine whether or not that will be necessary.

That's as far as I've gotten- it's now ready to be stapled and strung- and I'll add those pictures later.

I love sheer shade challenges! They're my favorite shades to make, and nearly every one presents a unique challenge. Finding the solution is my favorite part of my work.

Ta-da!

Subscribe to:

Posts (Atom)